ABOUT RADIANZA™

Radianza™ is one of

the most environment friendly and sustainable fibres made

by Gel-Dyeing technology.

Gel dyeing enables Radianza™ to consume much less resources and zero discharge of unused dyes as against the conventional yarn or fabric dyeing process.

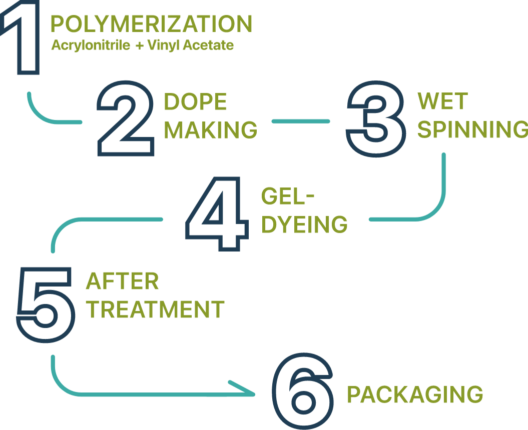

What is “Gel-Dyeing” technology?

Just after the spinning of polymer, the fiber obtained from the spinneret is highly amorphous and porous. It is neither completely solid nor completely liquid; it is in a gel-state. When the acrylic dye (basic dyes) solution is added in this stage, it gets immediately absorbed into the fibre without the need for additional water, chemicals or energy. Yarns or Fabrics made with 100% Radianza™ fibre need not be dyed again, so the step of yarn dyeing or fabric dyeing, which is a source of high pollution and resource consumption, could be avoided.

Radianza™ Production Process

Watch full documentary

Radianza™ — “Sustainable Fashion”

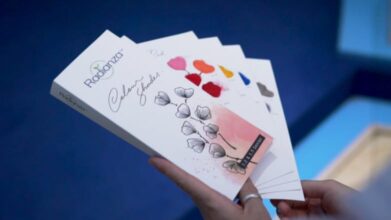

Radianza™ has a wide palette when it comes to shades. Till date there are close to 500 shades of Radianza™ produced. Not only one of the most vibrant colored fibres available today, Radianza™ has superb color fastness to light, washing and rubbing. We also have In-house Shade-matching capability as per customer’s requirement.

Visit “Radianza™ shadecard” for more information

Fibre Specifications

Radianza™ is available in a range of deniers and cut lengths.

Deniers: 1.2, 1.5, 2.5, 3.0 | Cut length: 38, 51, 64 | Forms: Staple fibre , Tow, Tops

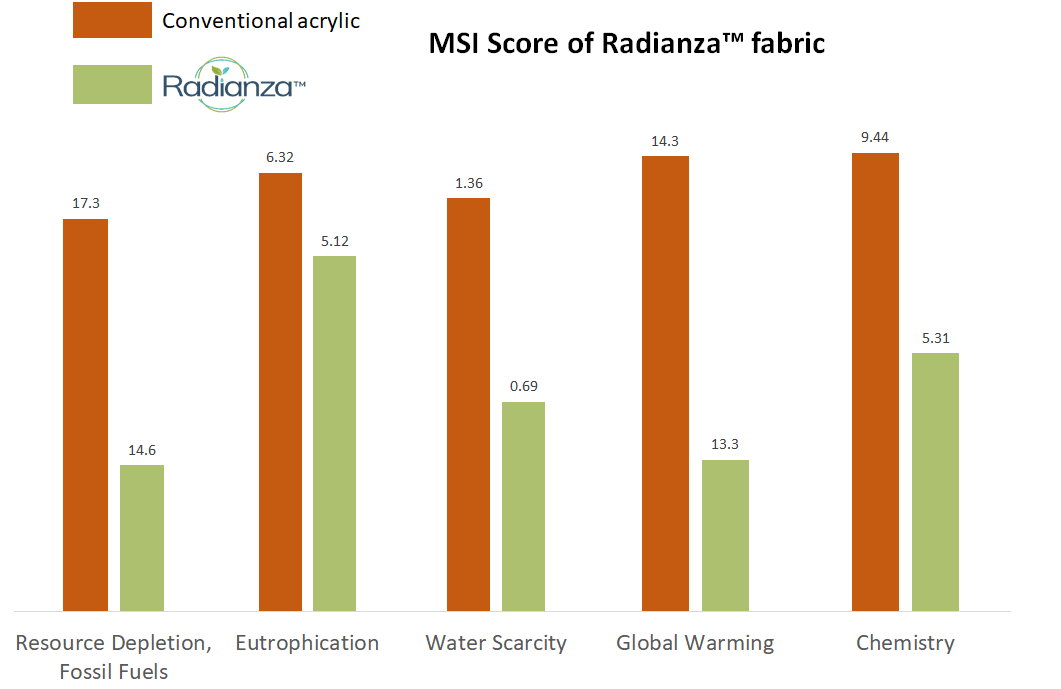

Material Sustainability Score (MSI) of Radianza™ by Higg Co.

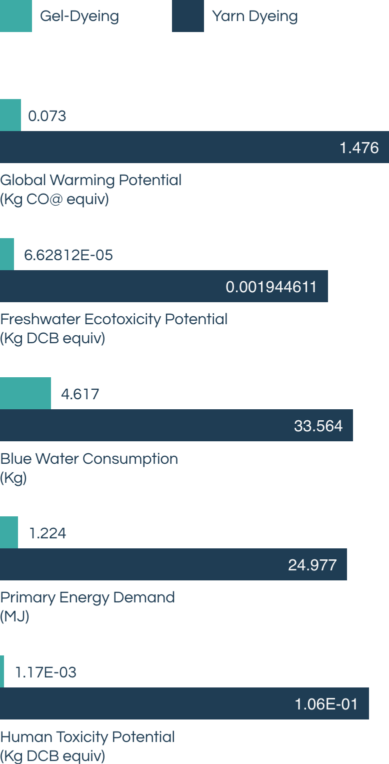

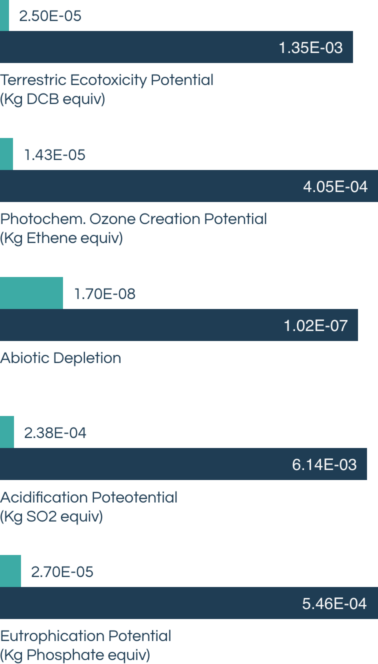

Gel-Dyeing v/s Traditional Dyeing

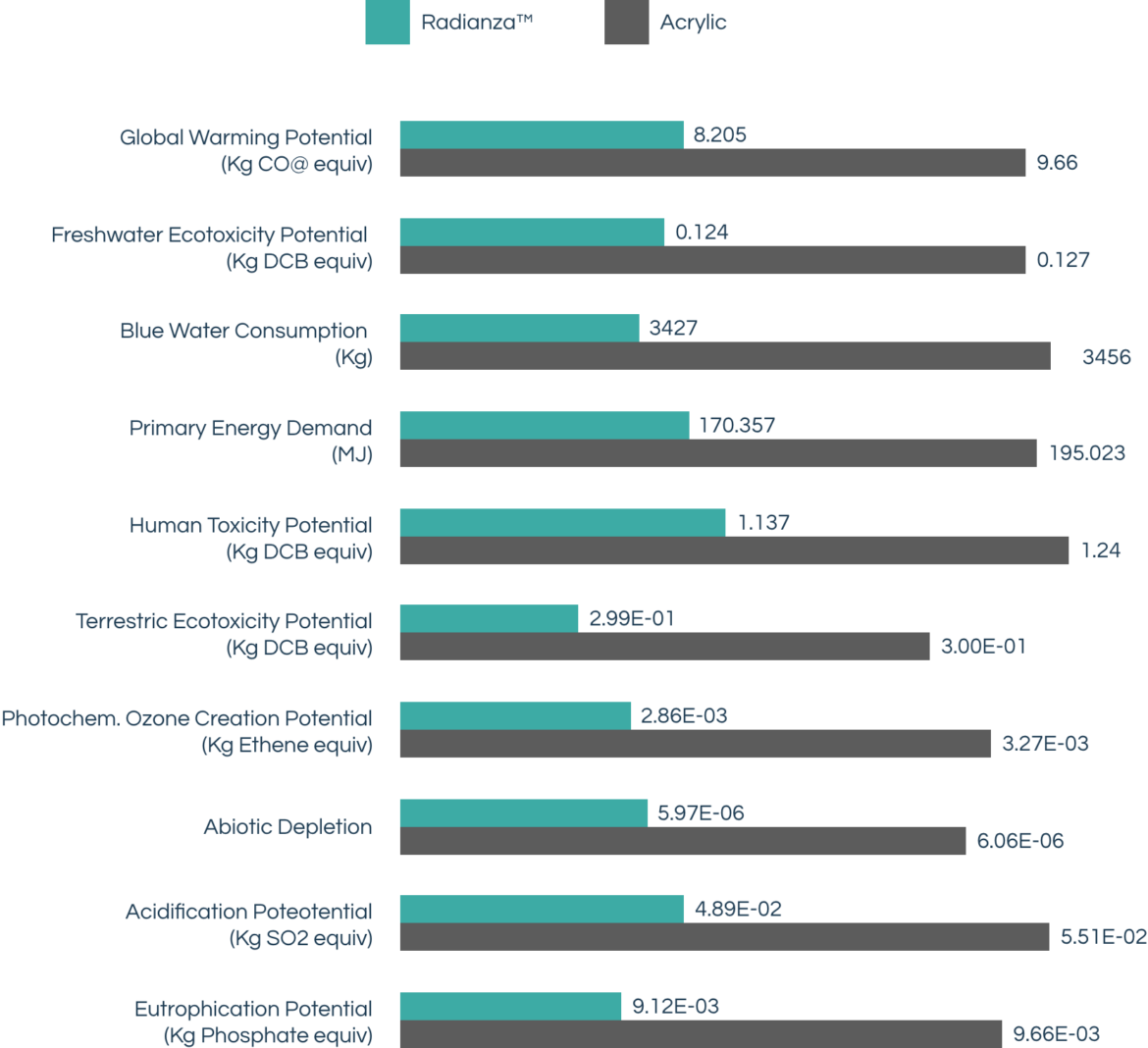

Fibre-to Garment Disposal

(Cradle-to-Grave)

Considering this is only for one sweater (approximately 450 g)

Life Cycle Analysis of Radianza™ shows that, using Radianza™ instead of regular fibre to produce one sweater, saves 30 litres of water, needs 25MJ less energy, and creates 1.45 kg less CO₂ emission.

Please send your enquiry, and we will send the full report upon your request.